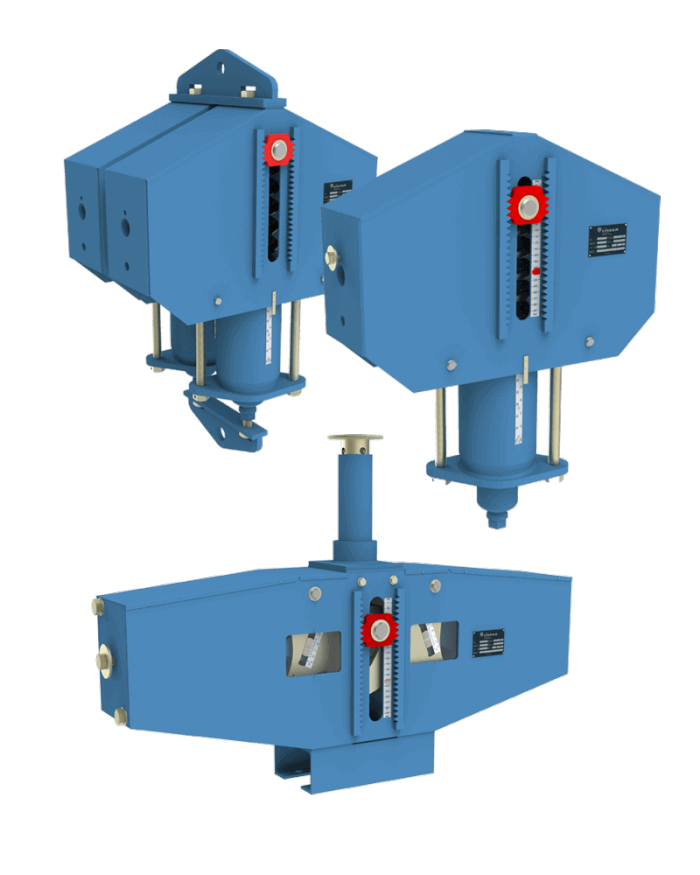

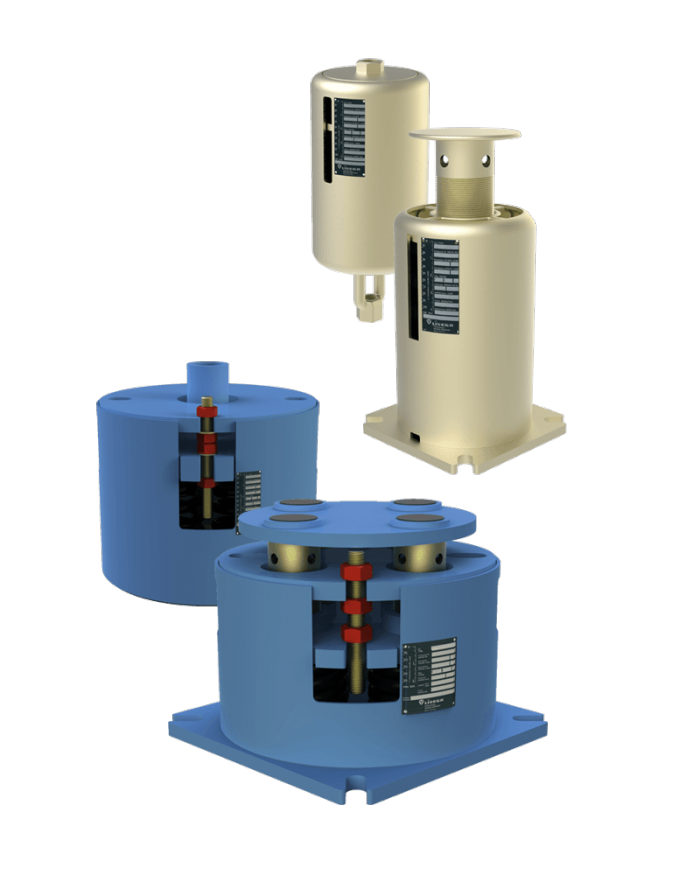

Constant hangers and constant supports

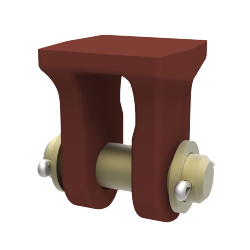

Constant hangers and constant supports have a special design that allows for transforming the spring force into a constant force through a large vertical displacement range

Download product catalog (metric)- Application

- Mode of operation

- Scope of performance

- LISEGA Benefits

- Connections

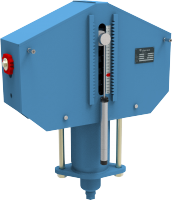

- Designs

- Mounting examples

- Products:

- Application

- Mode of operation

- Scope of performance

- LISEGA Benefits

- Connections

- Designs

- Mounting examples

- Products

Application

Constant hangers are used for piping and related components where higher levels of vertical travel occur. Their job is to transfer the working load over the whole travel area while keeping it constant, i.e. without any considerable deviations. The functional precision of the constant hangers is decisive for favourable long term behaviour of the components involved.

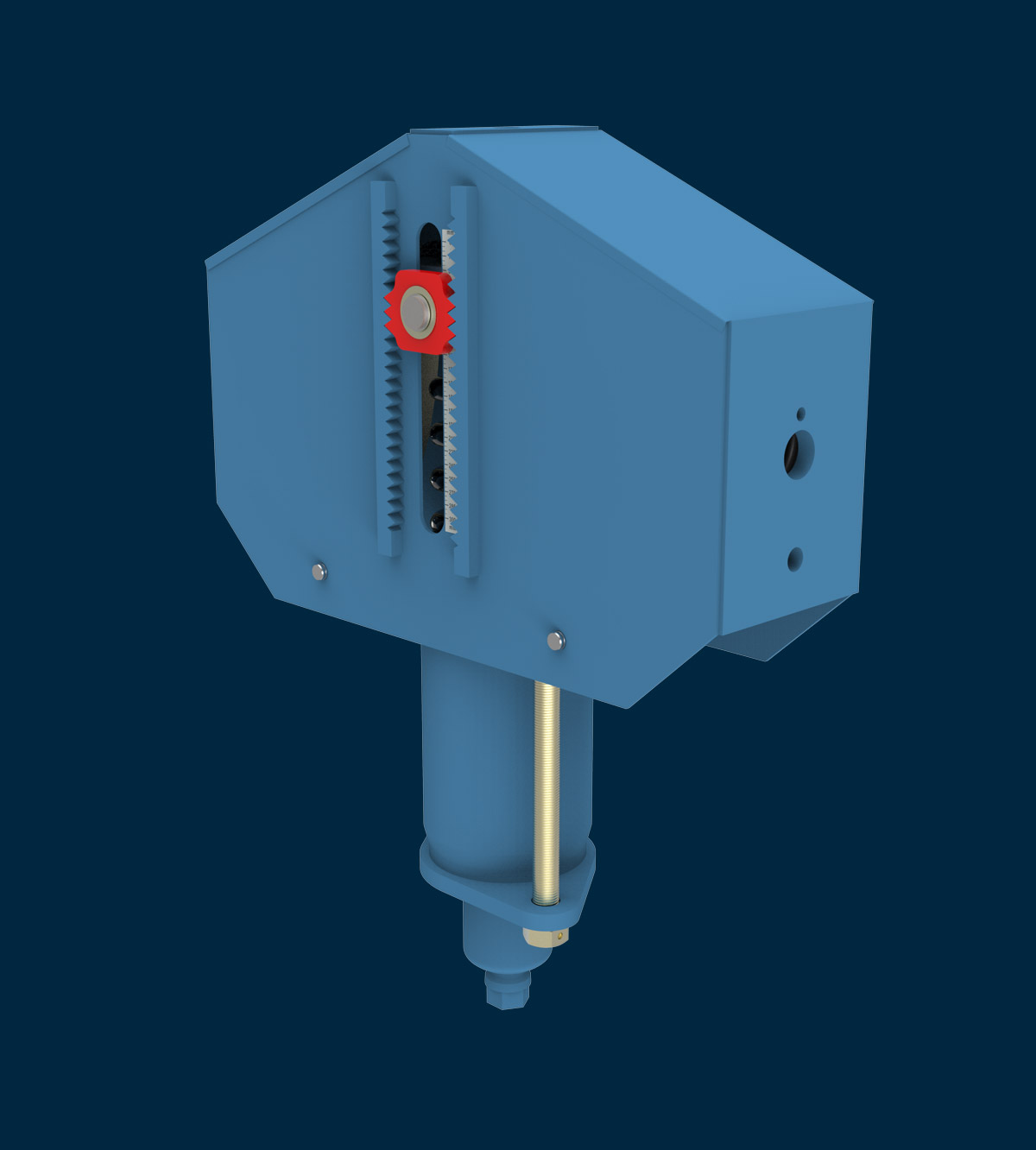

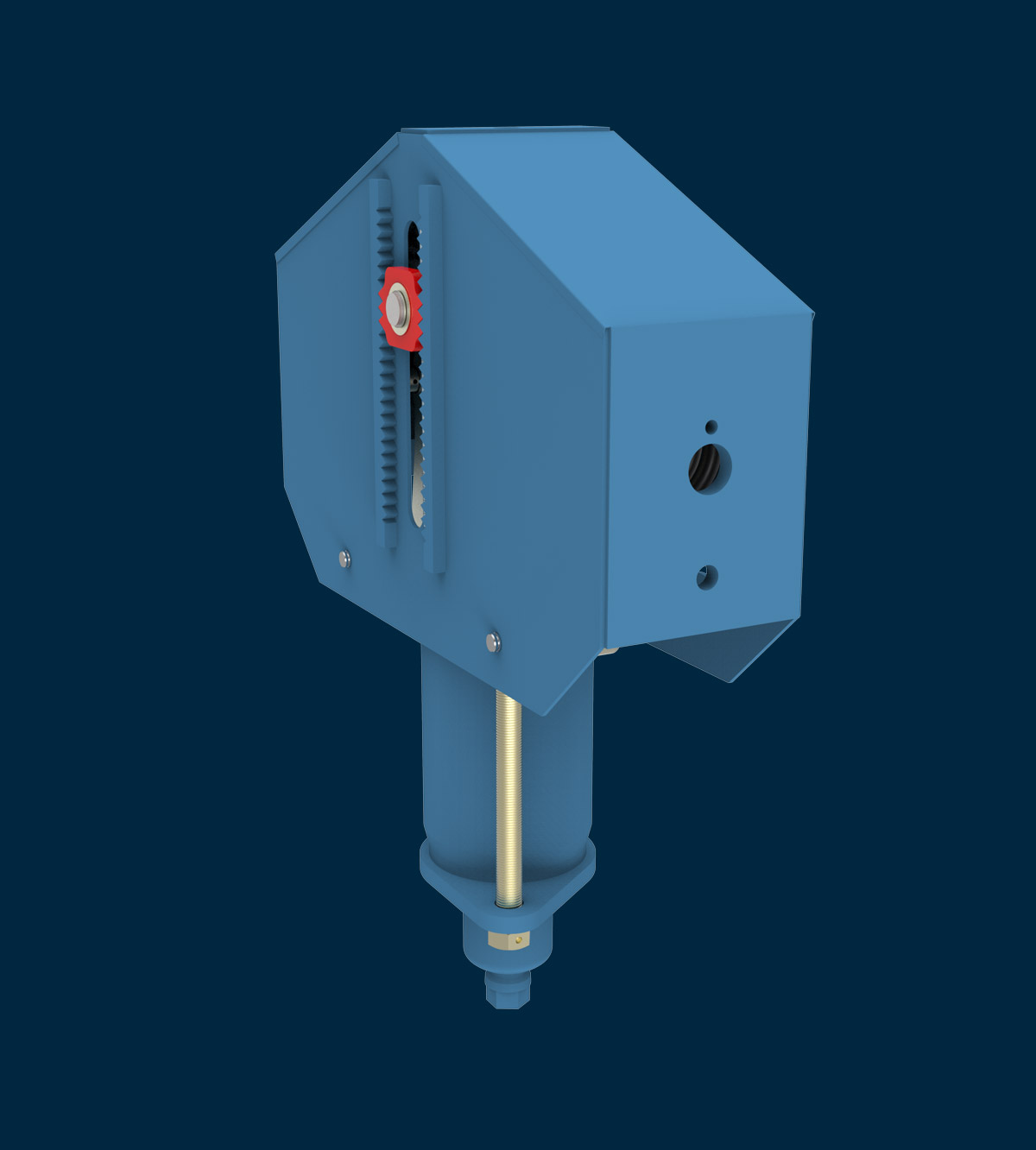

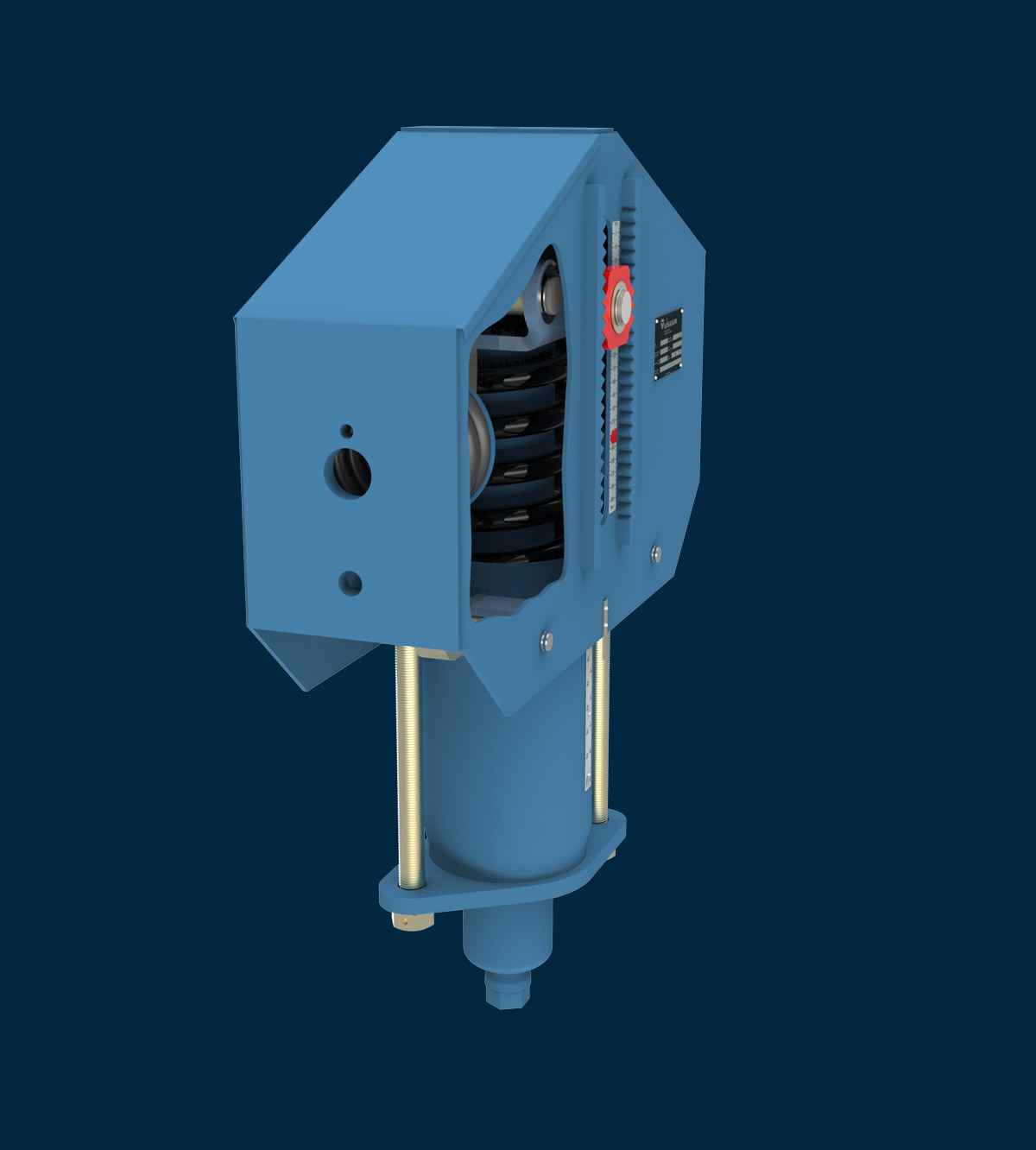

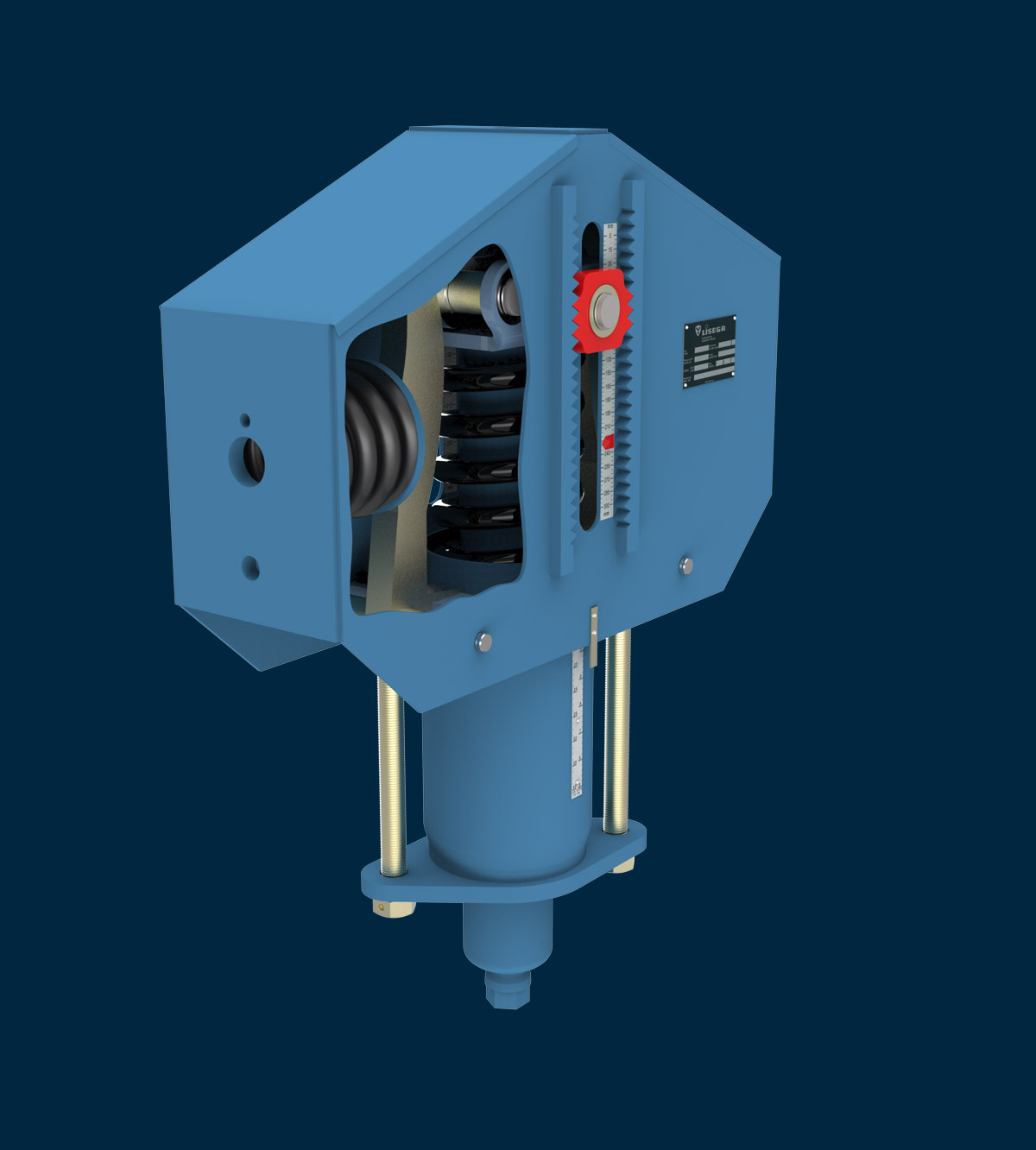

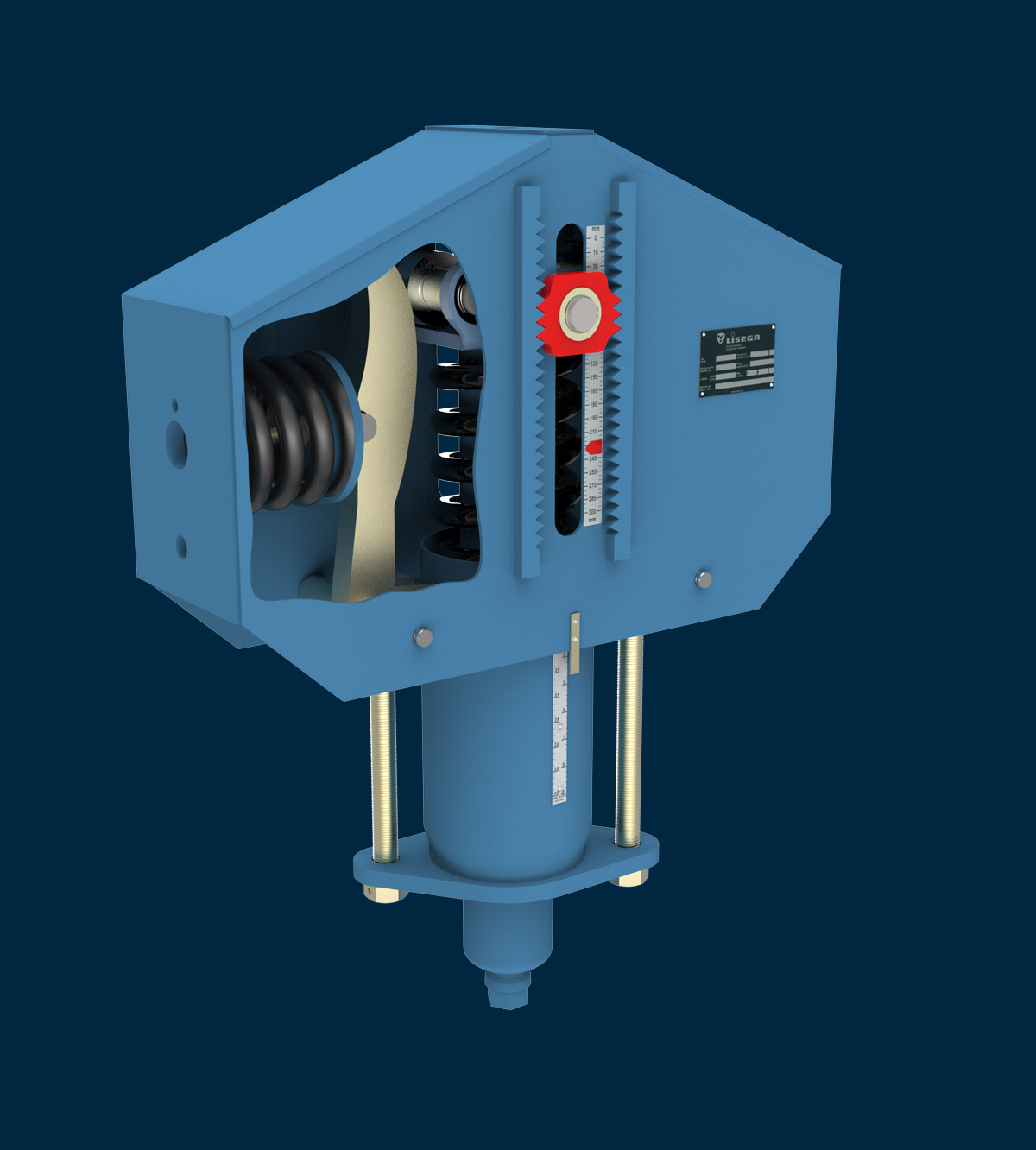

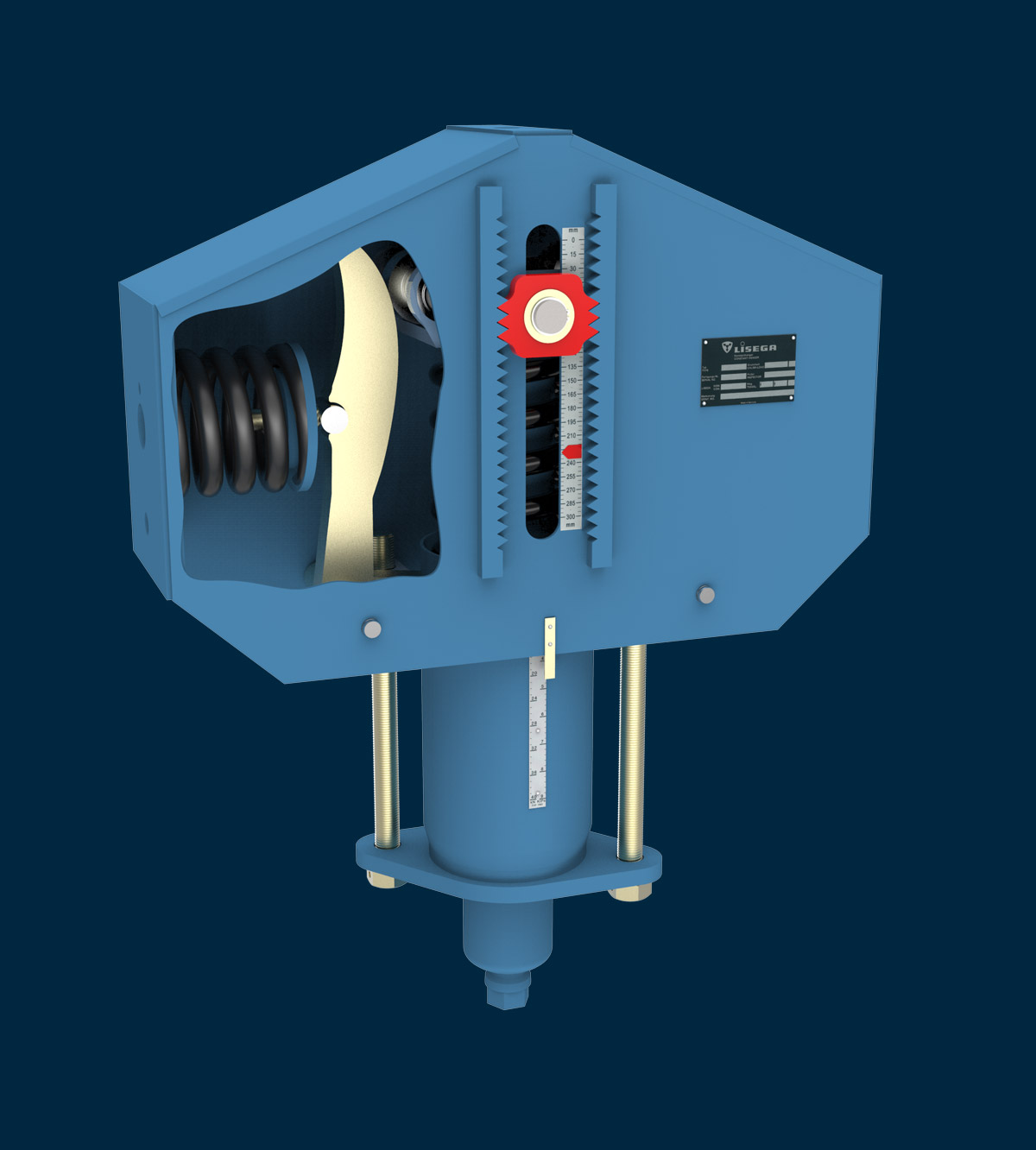

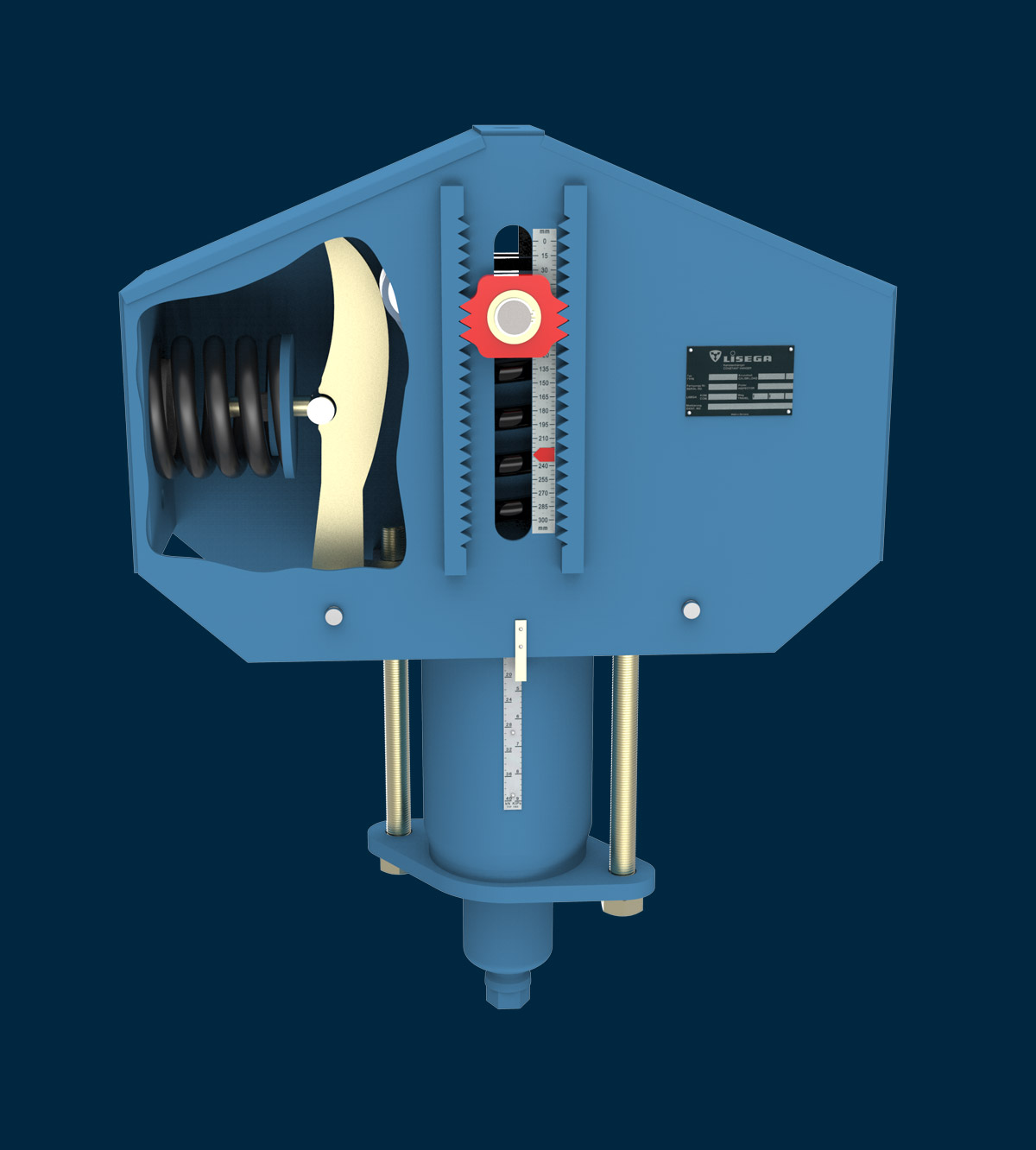

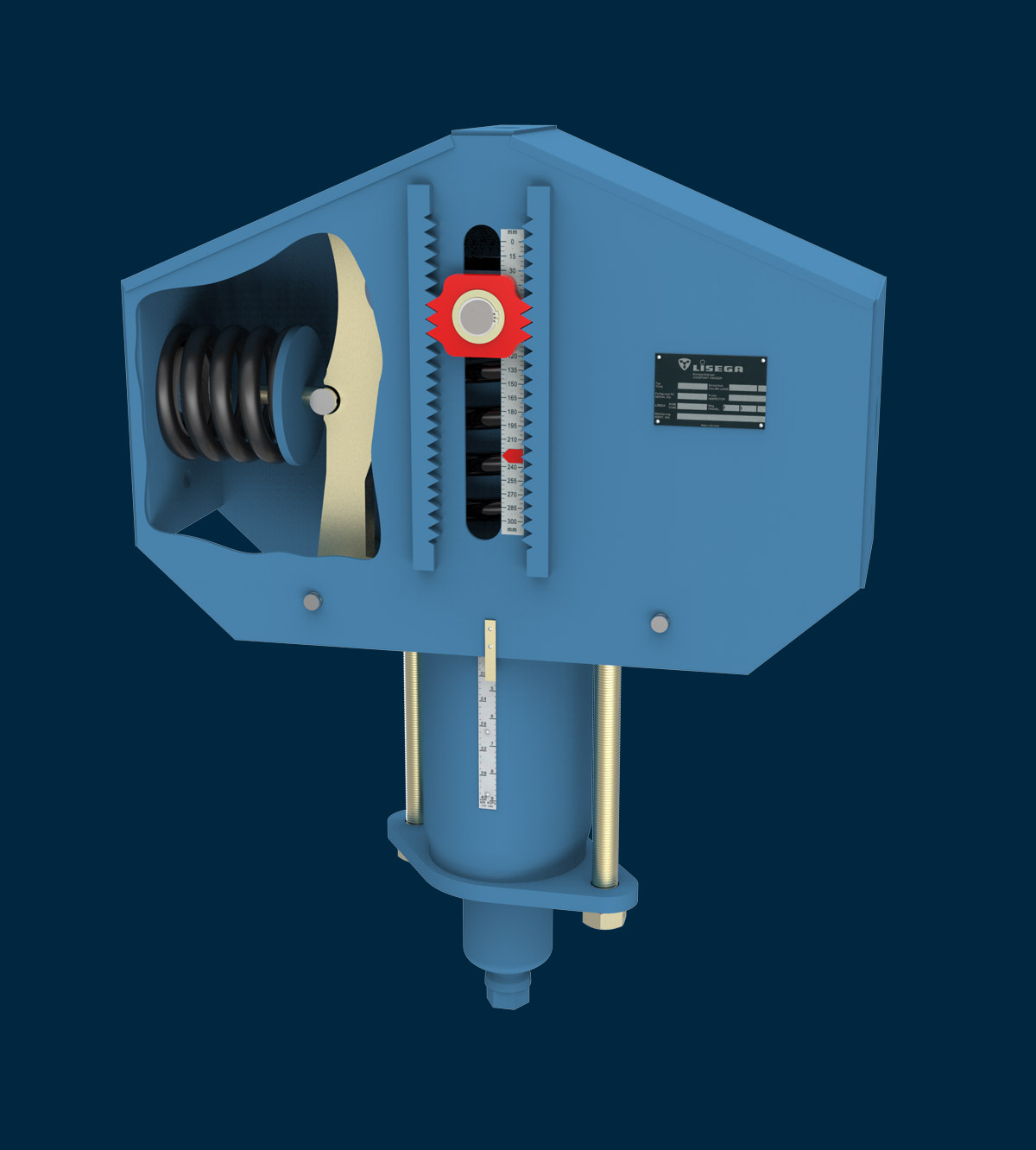

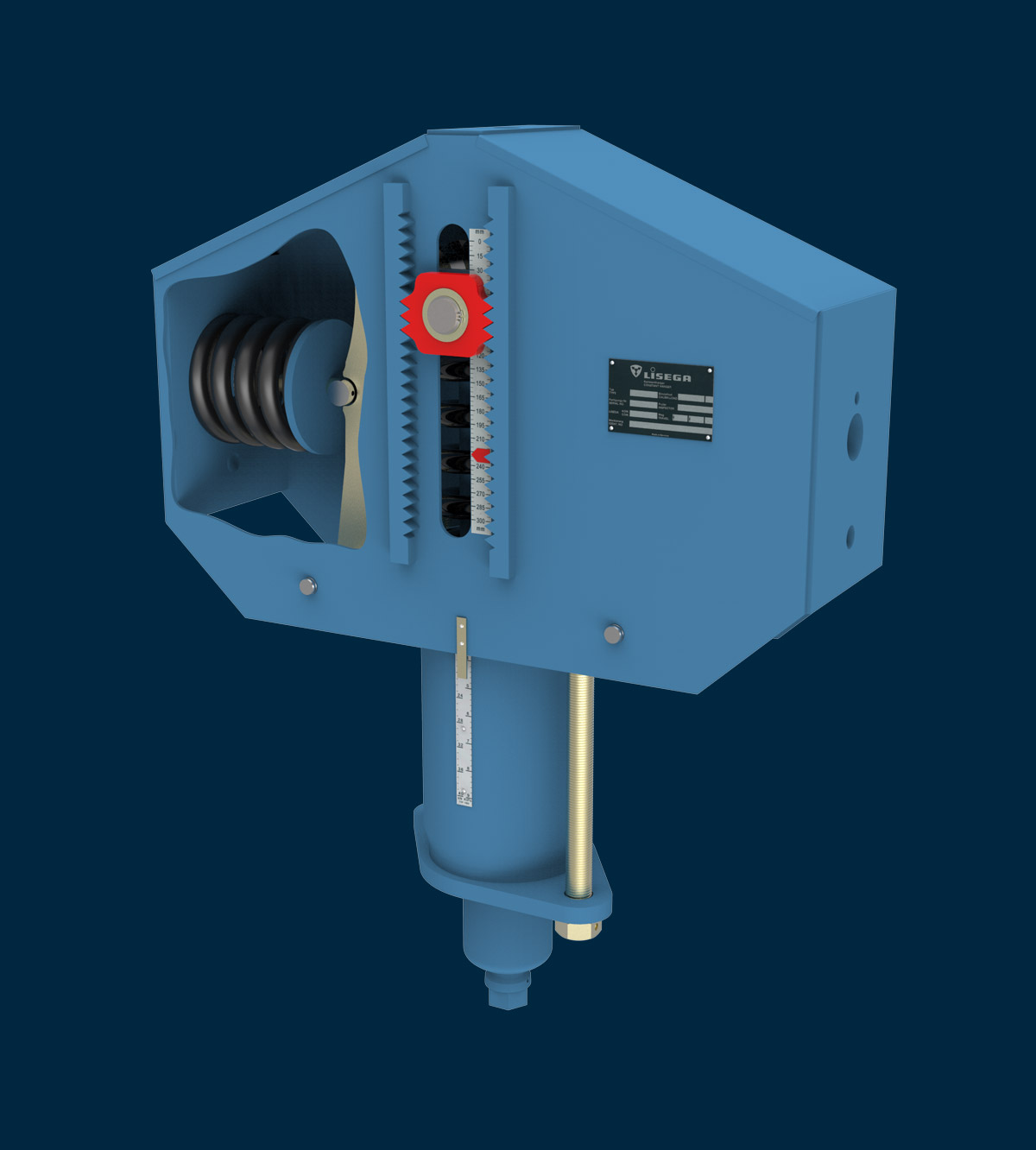

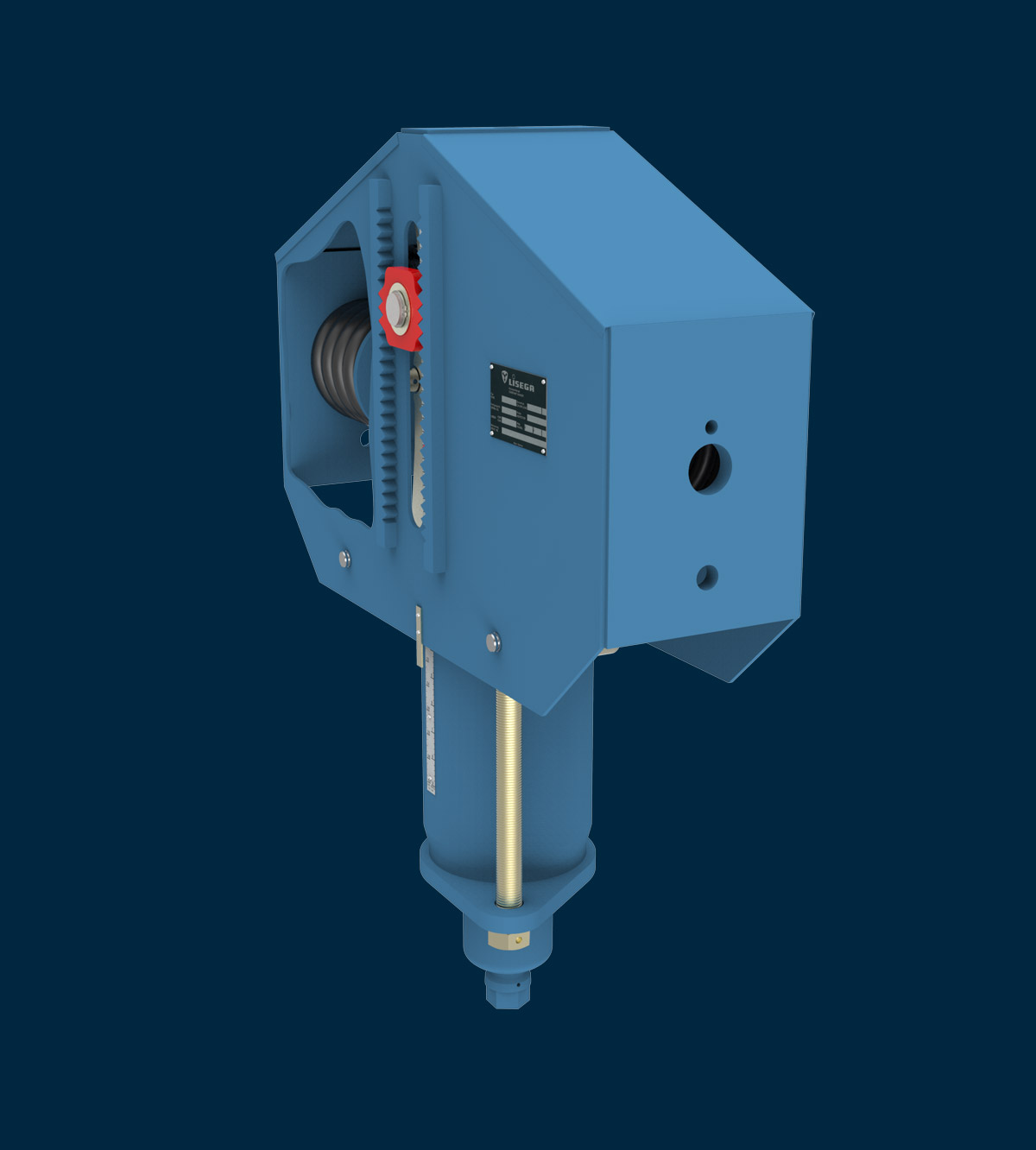

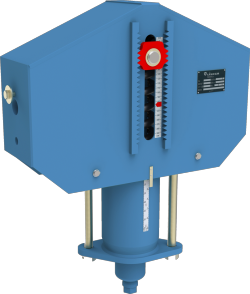

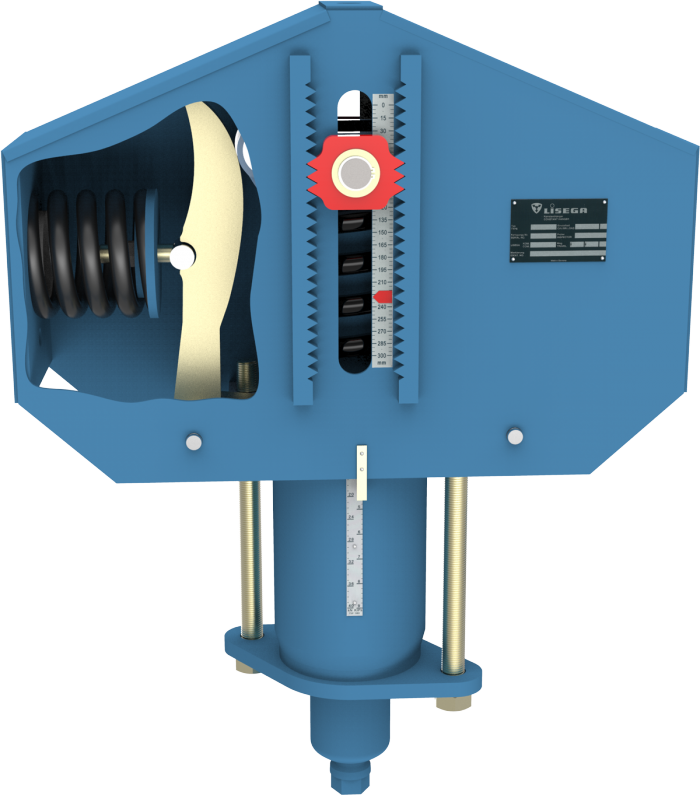

Mode of operation

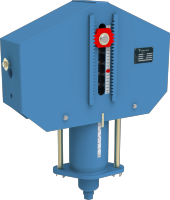

The mode of operation is based on the arrangement of three springs according to the parallelogram of forces. The design is distinguished by a high degree of functional precision along with wide load adjustment ranges.

Scope of performance

Load

0.13 kN to 500 kN / 29.23 lbf to 112,404.47 lbf

Travel range

up to 900 mm / 35.43 in

LISEGA Benefits

Our constant hangers and constant supports offer the user a large number of special benefits:

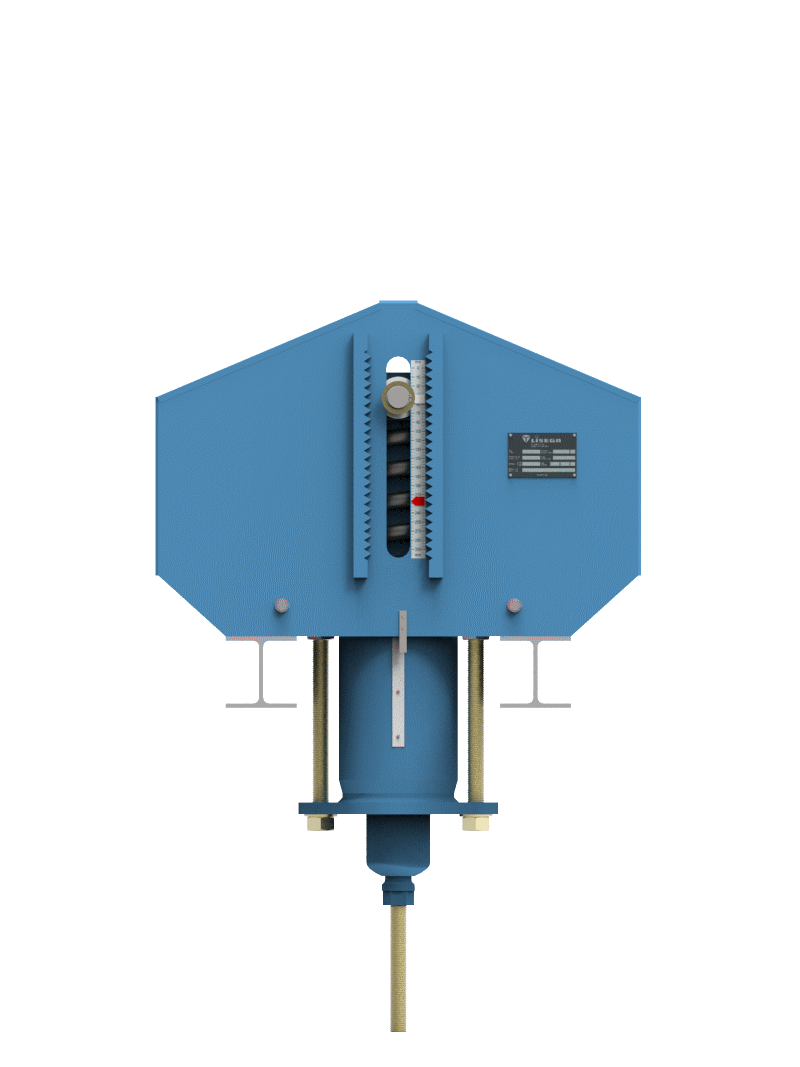

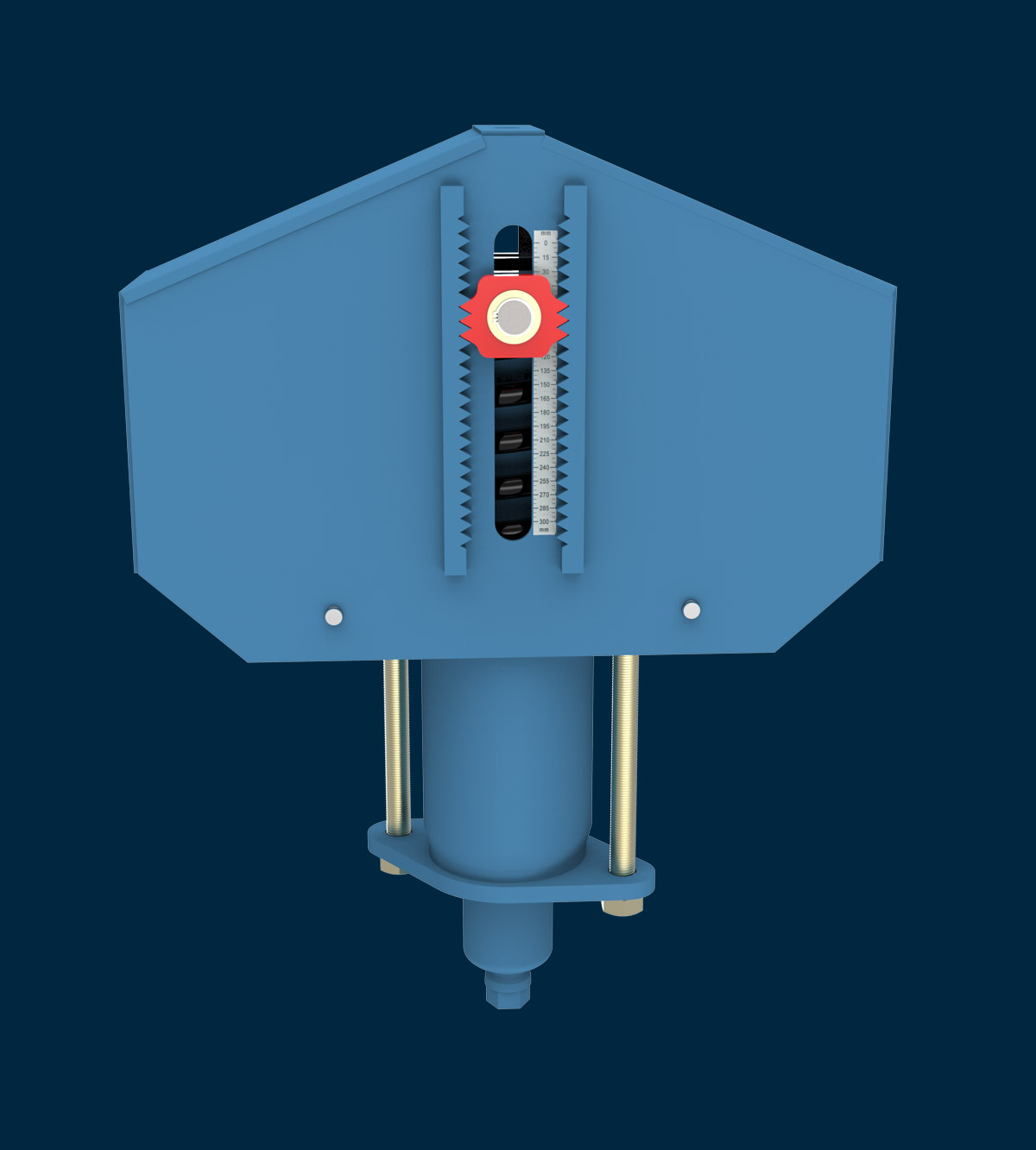

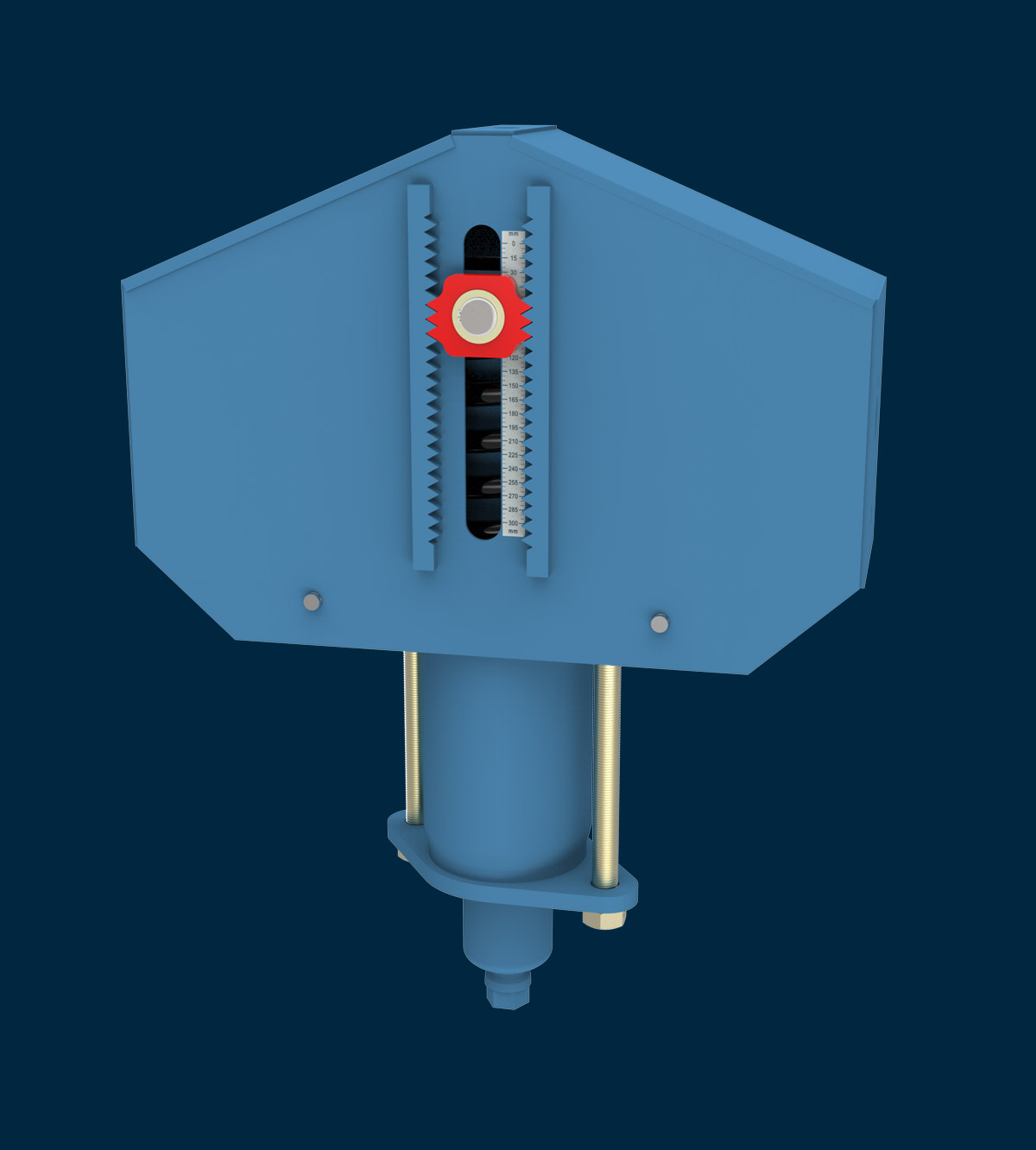

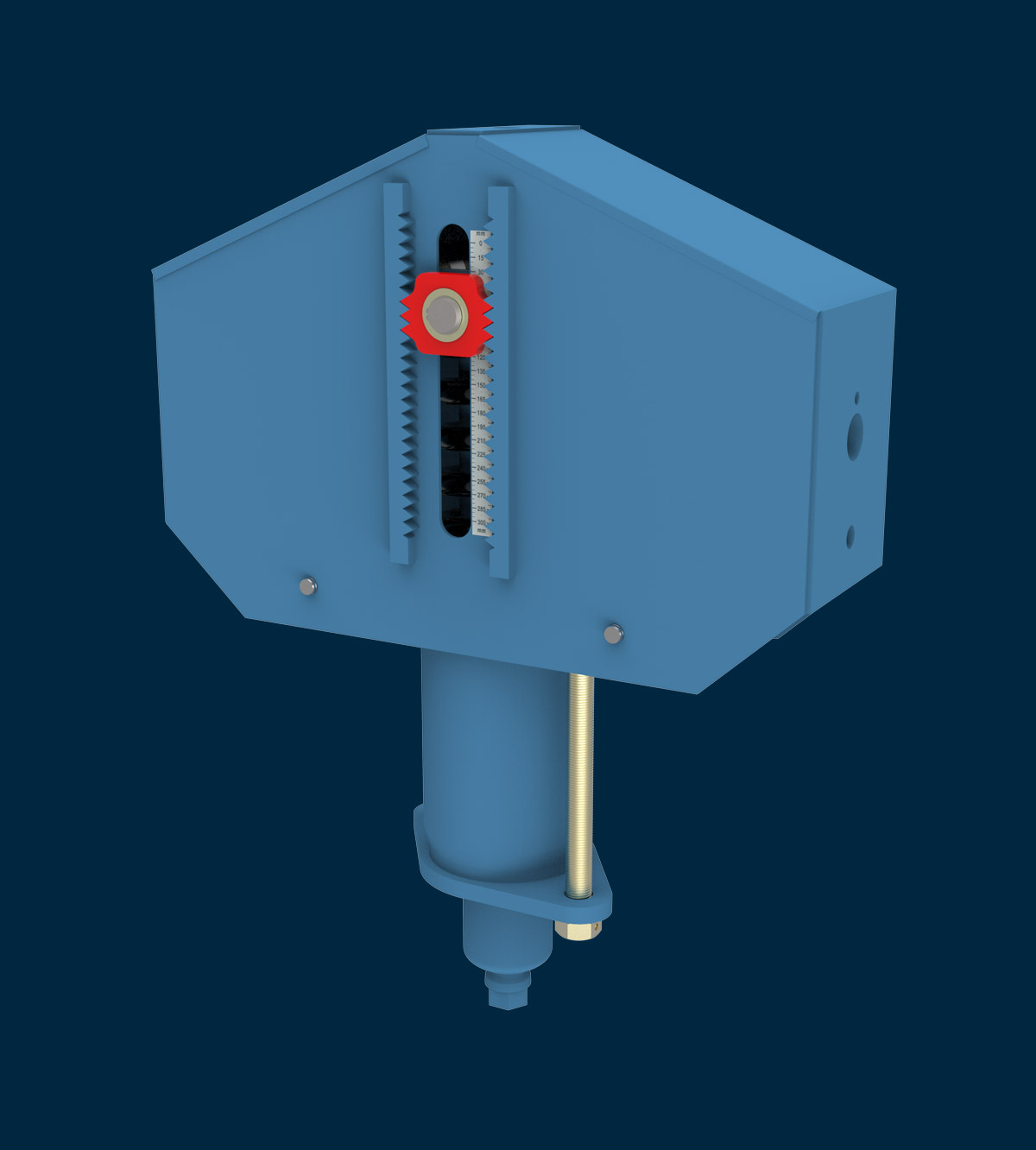

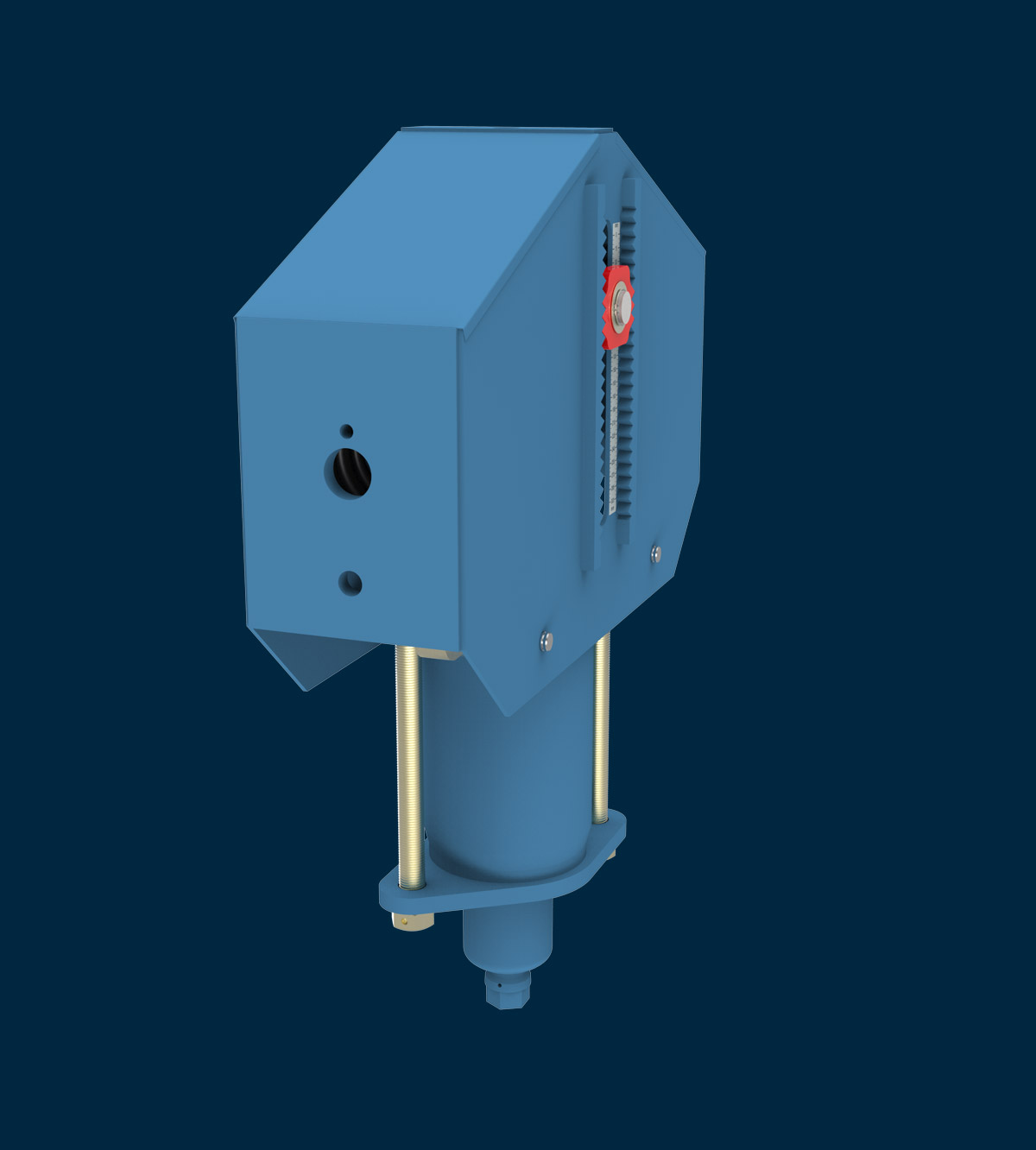

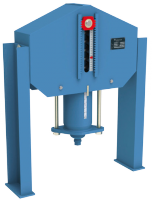

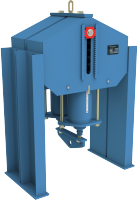

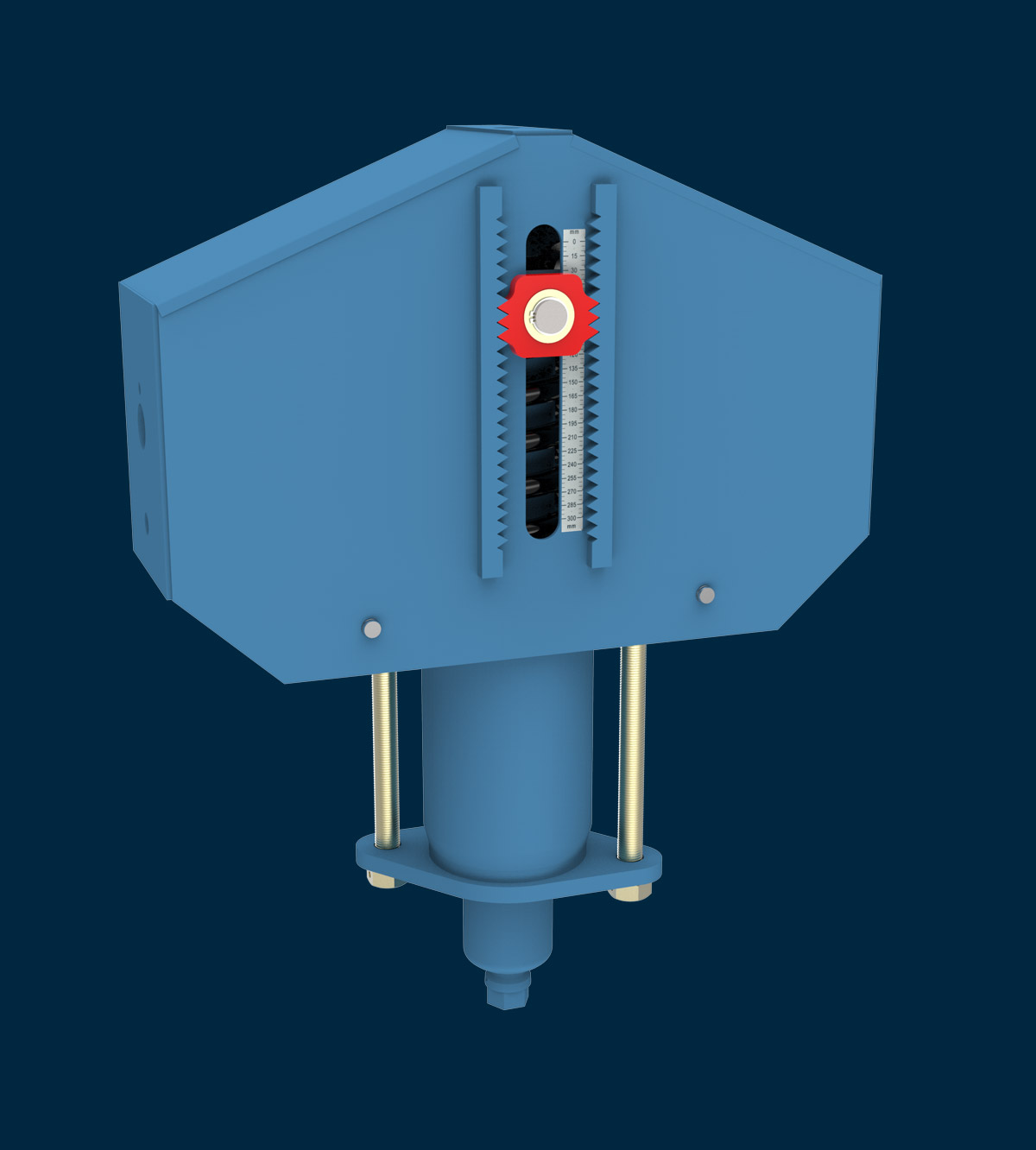

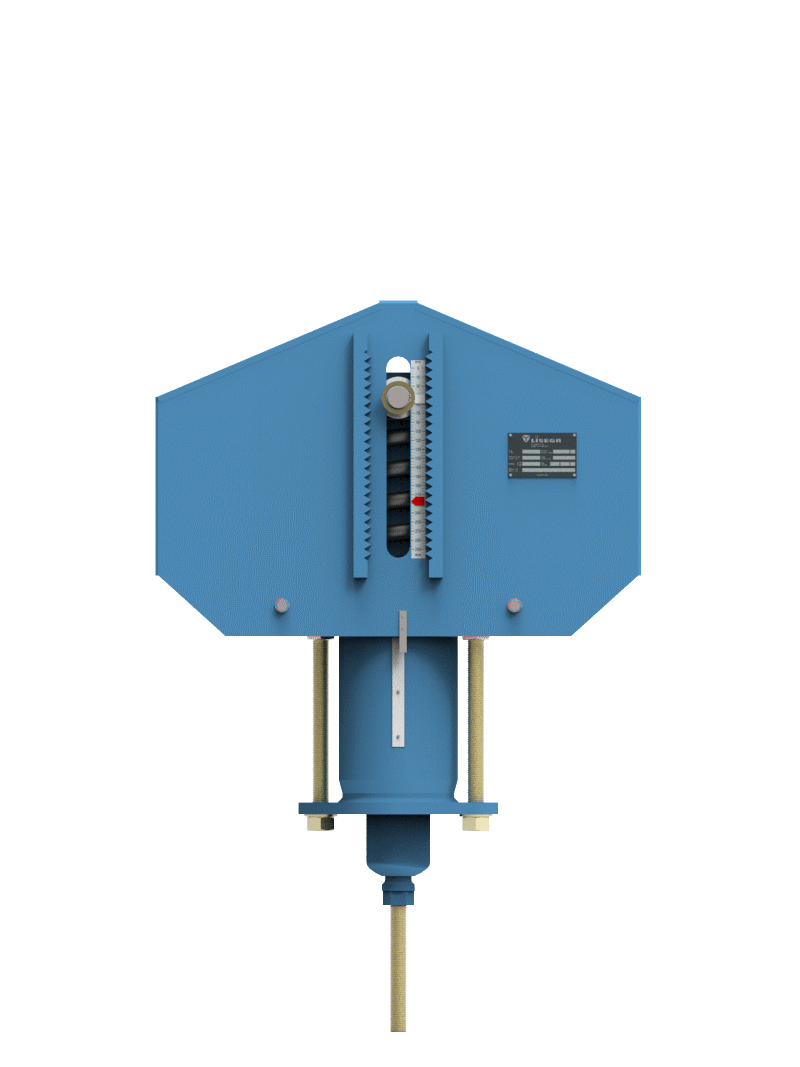

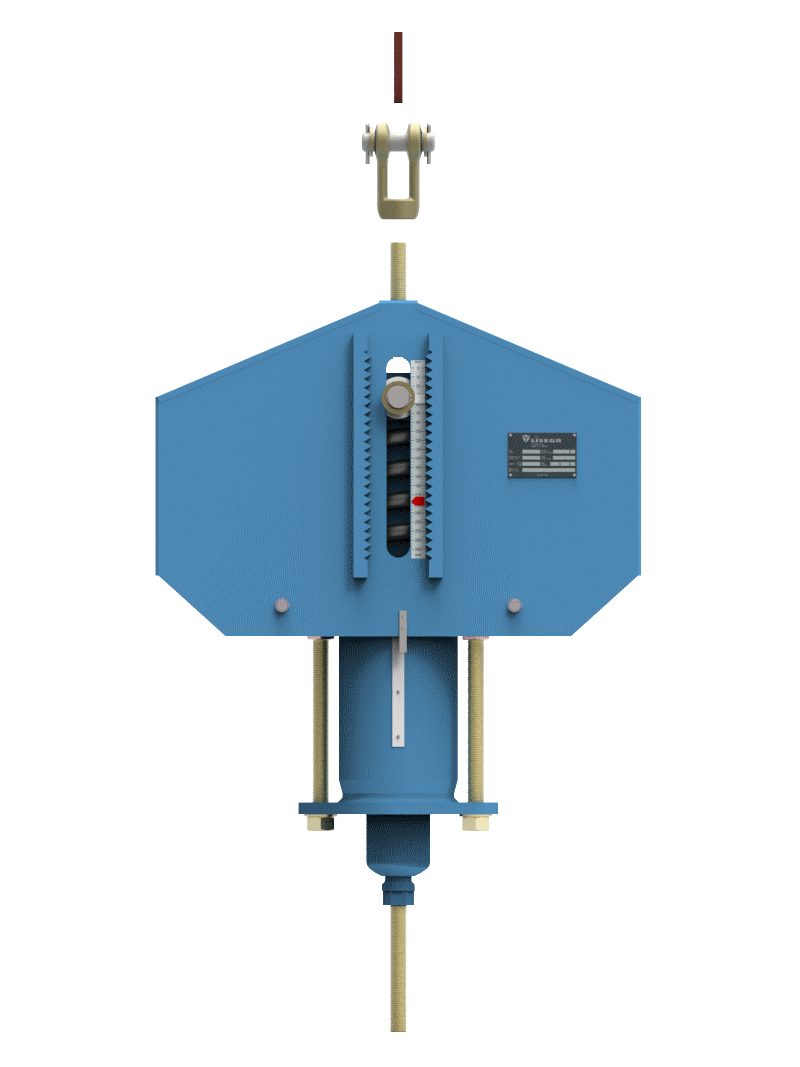

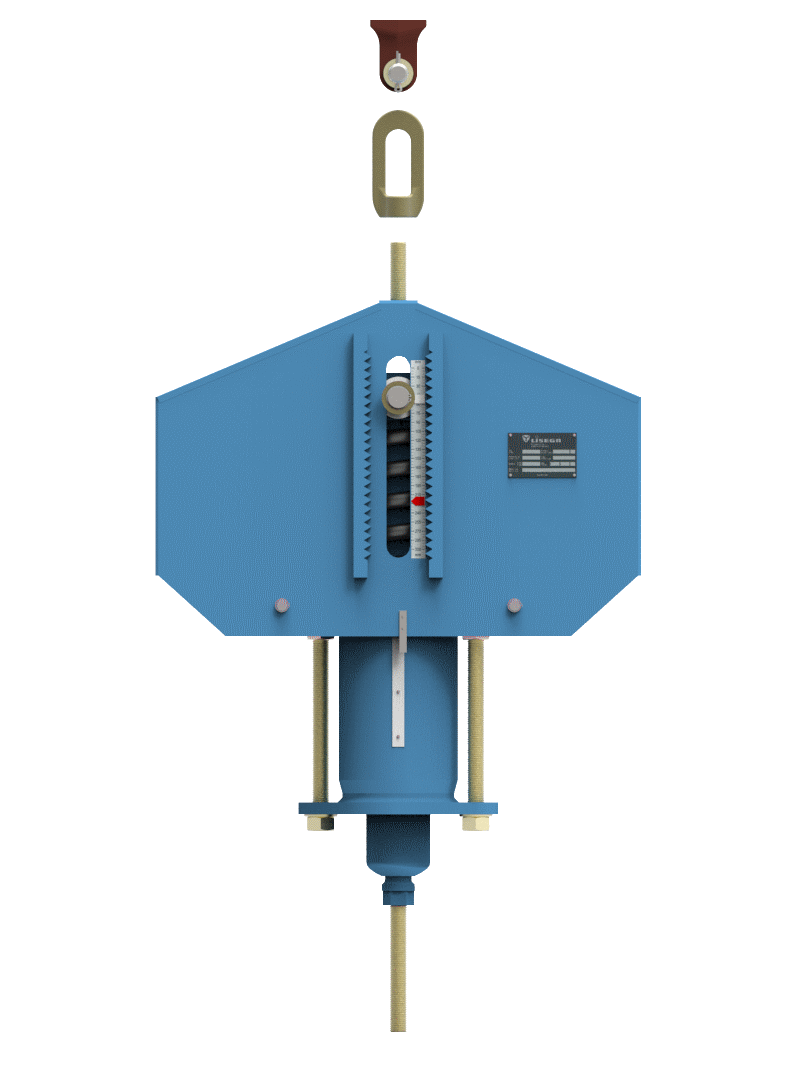

- front view

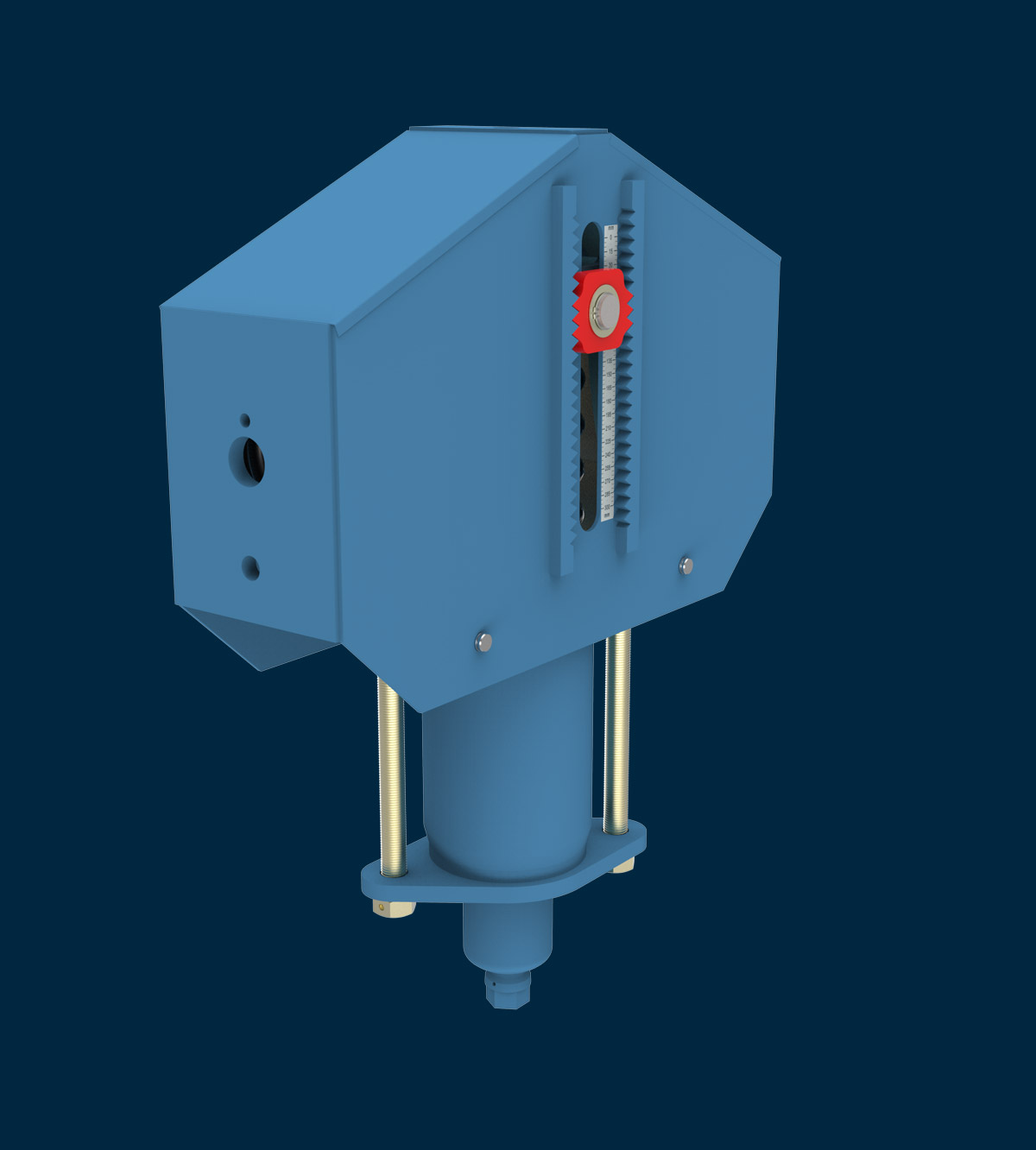

- rear view

Principle-based constancy by way of a special mode of operation.

Pre-relaxed springs eliminate any significant loss of load-bearing capacity.

Reduced friction due to minimised number of bearing points.

Name plate contains complete technical specifications.

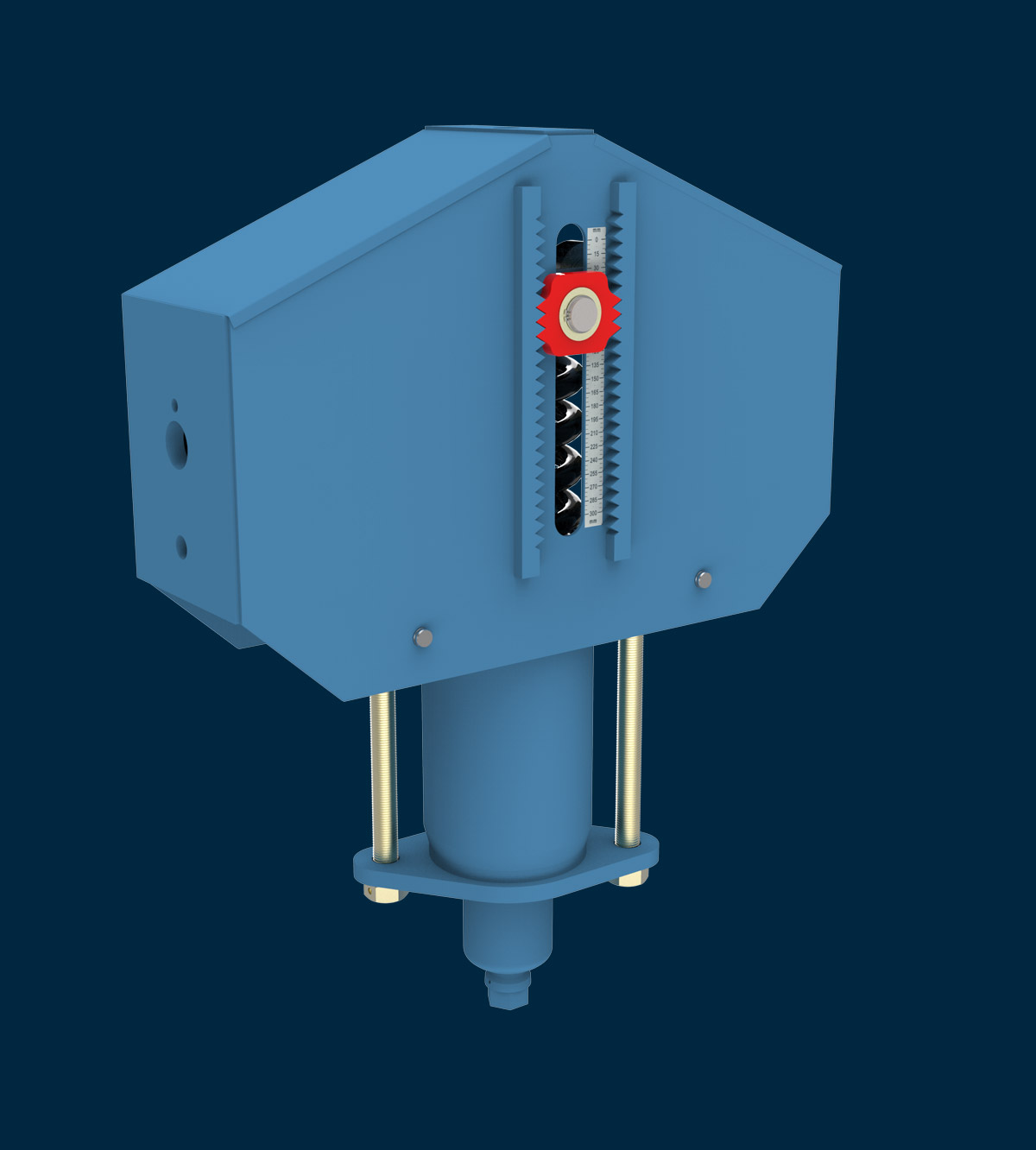

Directly readable travel scale with marking for hot/cold load positions.

Load scale with permanent marking of adjustment load.

Turnbuckle function allows re-adjustment of pipe installation position.

Torque-free load application due to a single suspension point.

Blocking is adjustable to practically any travel position through fine-tooth notching.

Exceptionally wide load adjustment range helps to avoid hanger replacement when operational loads change.

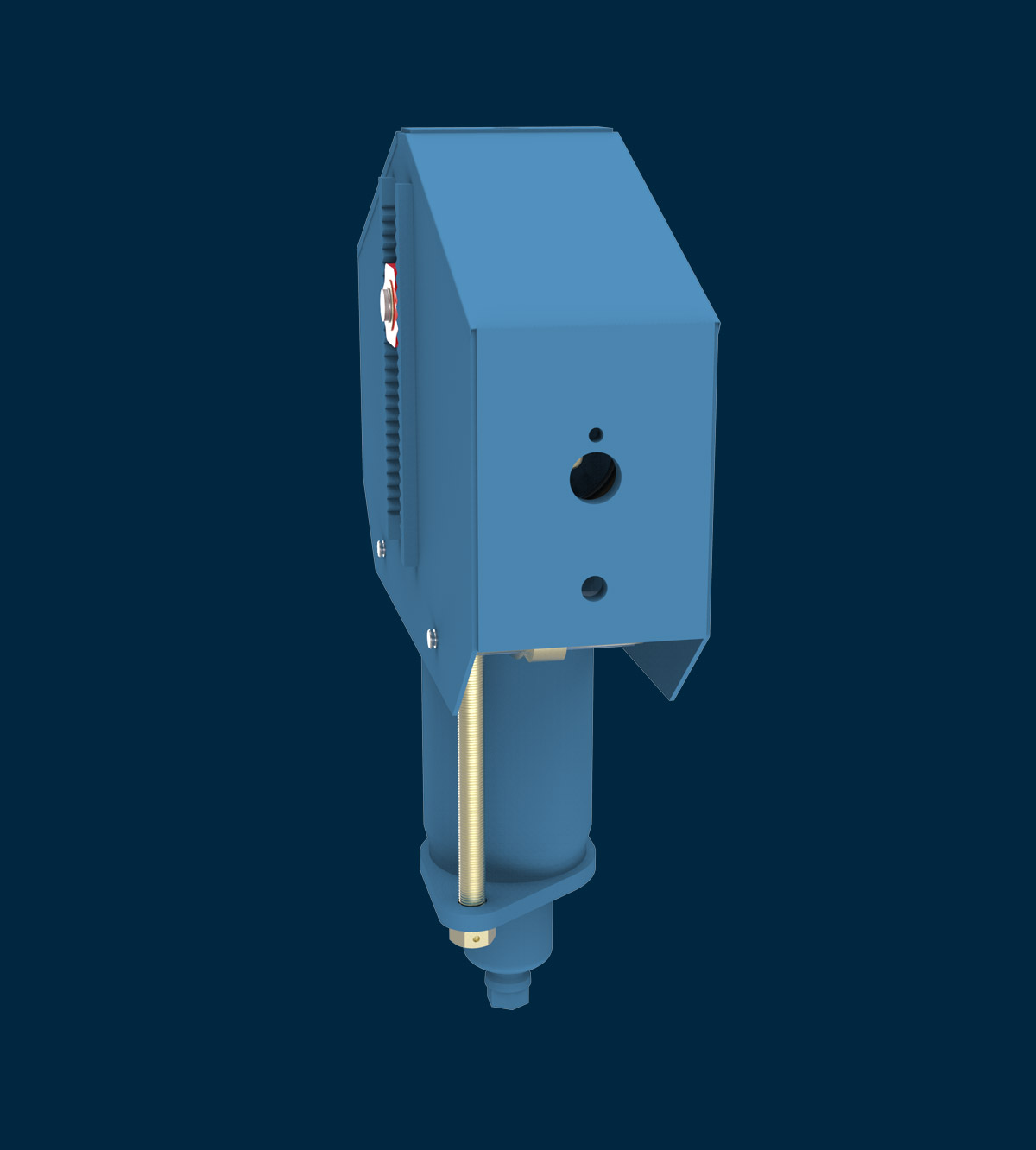

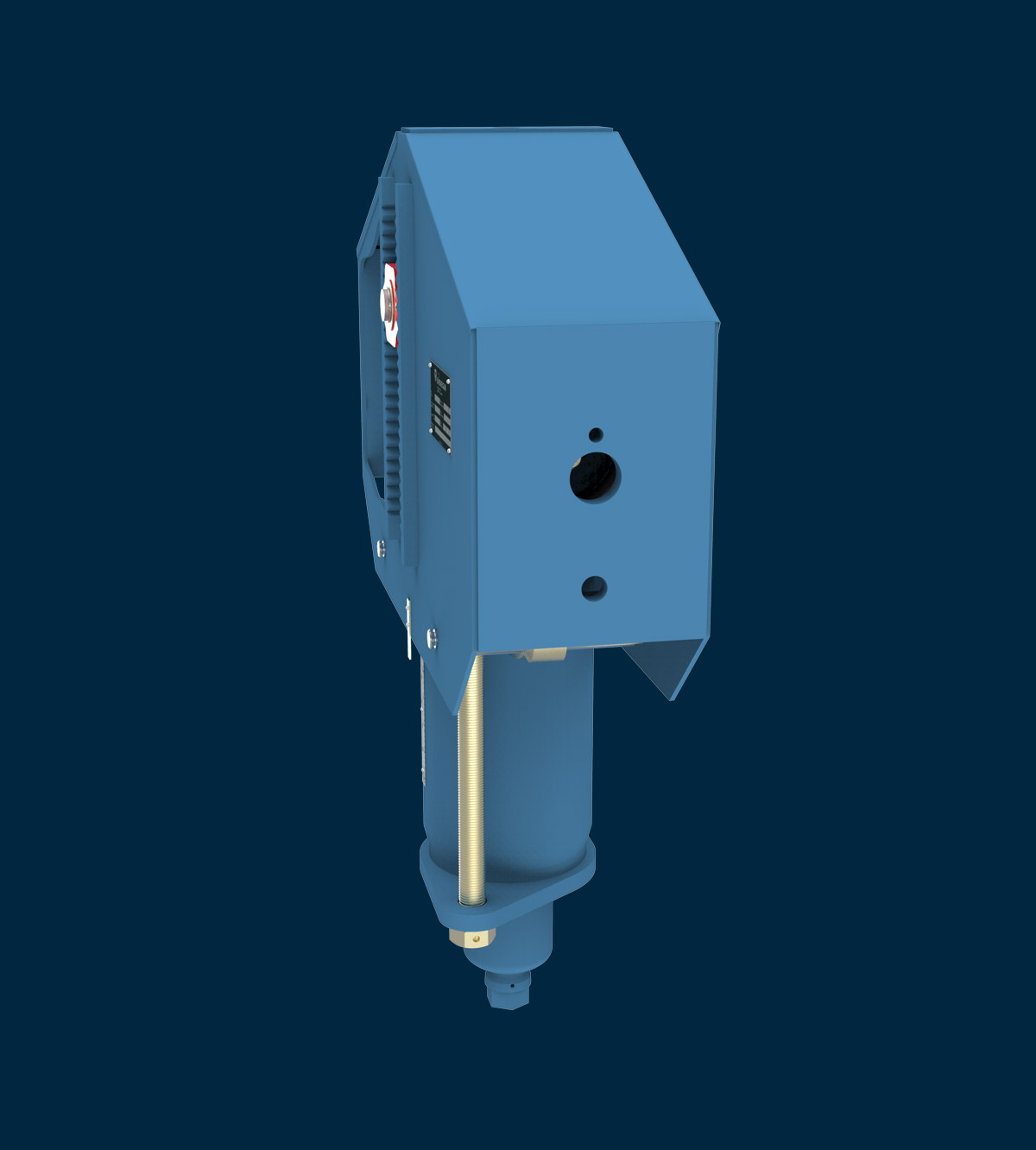

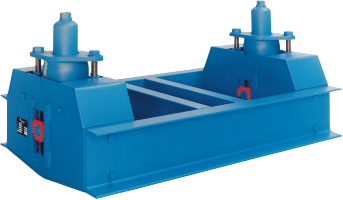

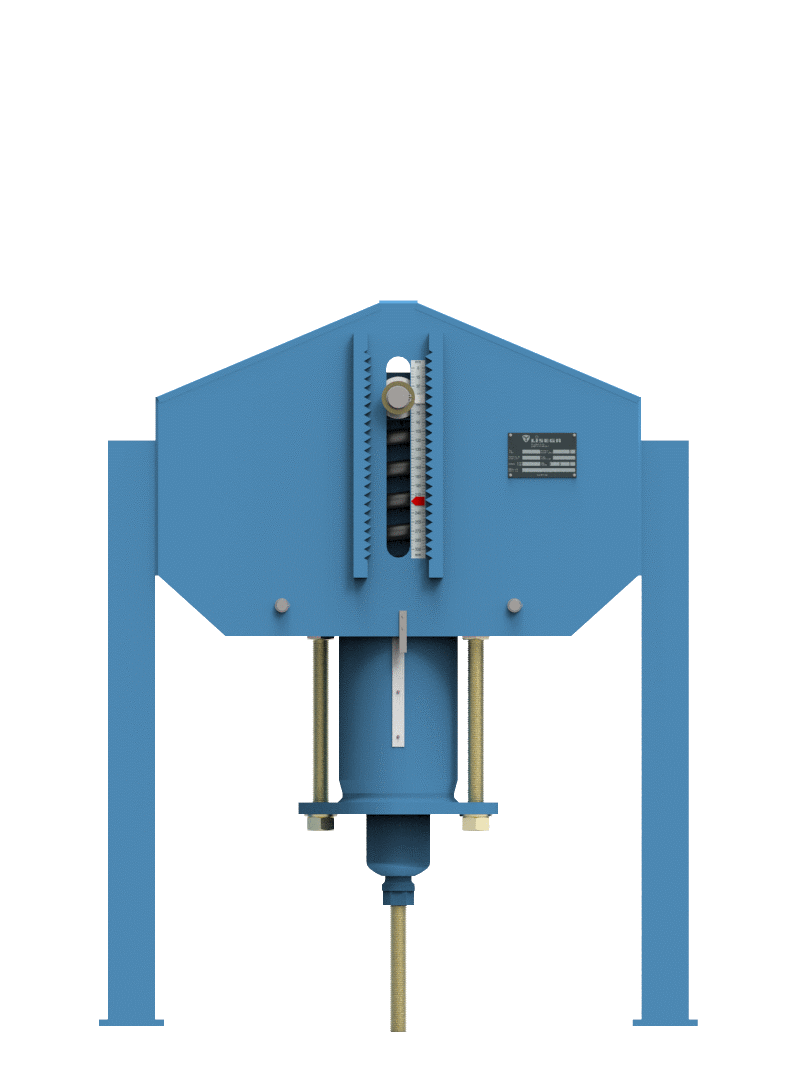

- Symmetrical design ensures direct flow of forces through axis of symmetry.

- Favourable power-weight ratios for reduced installation loads.

- Arranged by load groups and travel ranges to simplify selection (modular system).

- Consistent functional behaviour due to high-quality corrosion protection and maintenance-free, chemically nickel-plated finishes.

- Readily adaptable to the installation situation due to suitable designs and standardised accessories.

- Double load-tube guiding of constant supports for transmission of side loads.

- Secure connection of load chains due to load- and connection-compatible modular components.

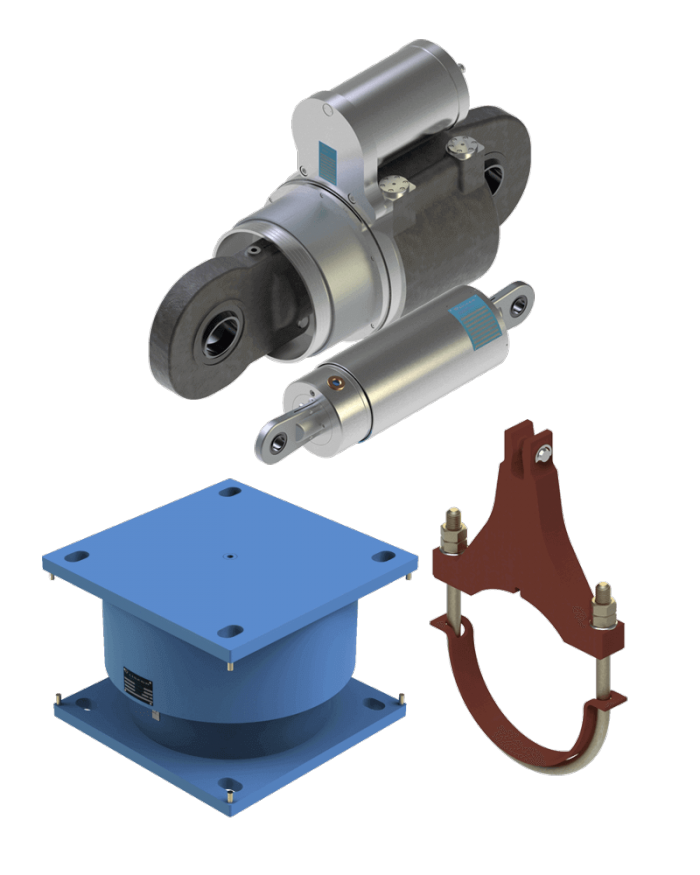

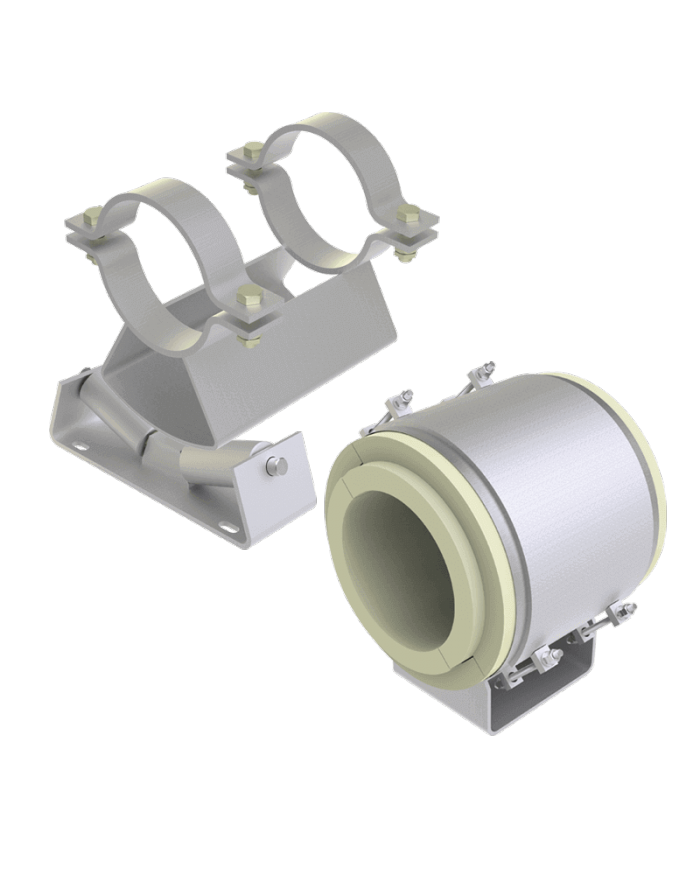

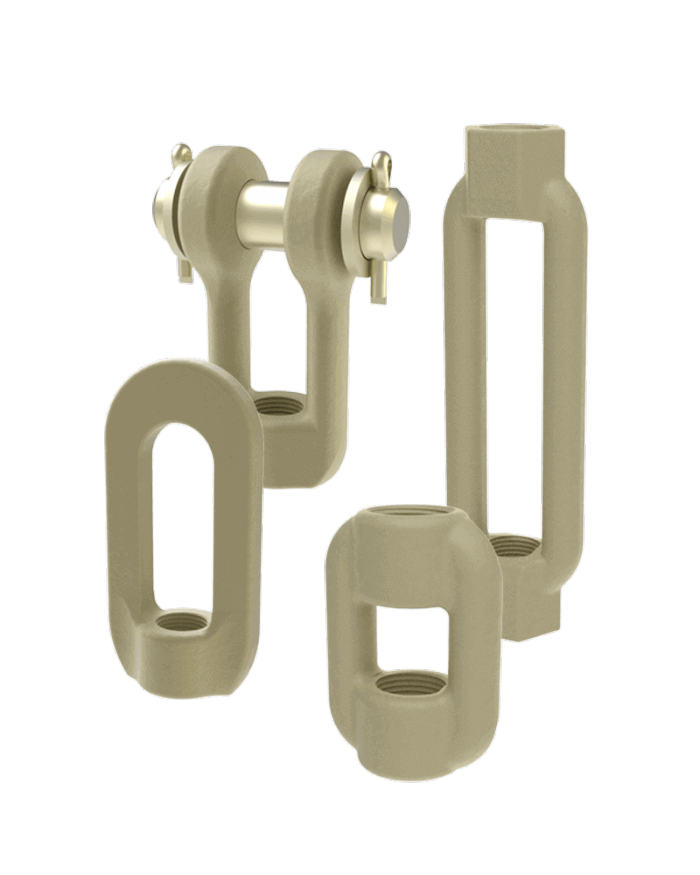

Connections

Weld-on eye plate type 75

CloseThreaded clevis type 61

CloseStud bolt type 67

Close

Weld-on clevis type 73

CloseEye nut type 60

CloseStud bolt type 67

Close

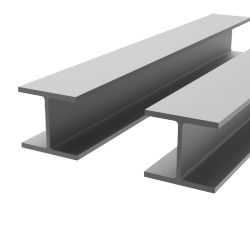

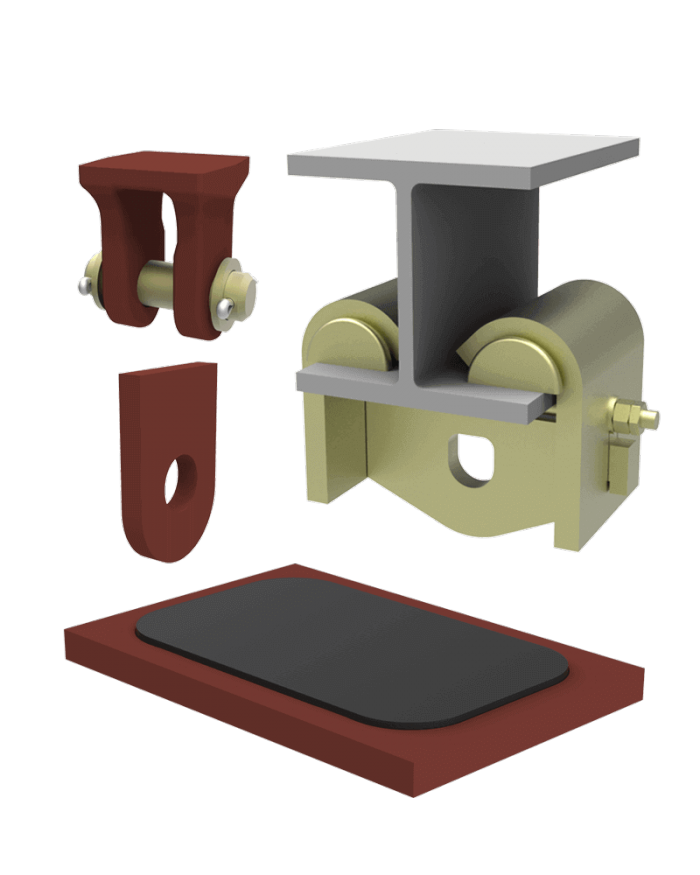

Supported by brackets type 71

Close

Supported by on-site steel construction

Close